Article Source:本站 Reading volume: 次 release time:2021-10-29

Ultrasonic testing (UT) is one of the methods of non-destructive testing in industry. When an ultrasonic wave enters an object and encounters a defect, a part of the sound wave will be reflected. The transmitter and receiver can analyze the reflected wave, and the defect can be detected extremely accurately. And can display the location and size of internal defects, determine the thickness of materials, etc.

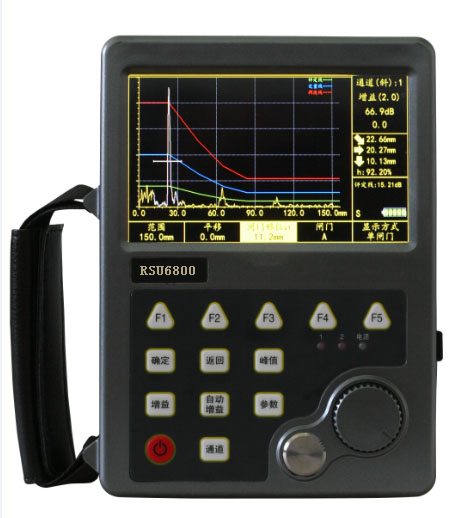

Pulse echo testing is usually used for forgings, welds and castings. Small cracks, slag inclusions, shrinkage holes, incomplete penetration and other defects can be found inside the workpiece. The object to be detected is required to have a simple shape and a certain surface finish. In order to quickly inspect pipes, bars, steel plates and other profiles in batches, an ultrasonic flaw detection system equipped with mechanical transmission, automatic alarm, marking and sorting devices can be used. In addition to flaw detection, ultrasound can also be used to determine the thickness of materials. The most widely used digital ultrasonic thickness gauge is the same as the pulse echo flaw detection method. It can be used to determine the thickness of chemical pipelines, ship hull steel plates and other corrosive objects. By measuring the speed of sound, attenuation or resonance frequency of ultrasonic in the material, the grain size, elastic modulus (see tensile test), hardness, internal stress, hardened layer depth of steel, and spheroidization degree of ductile iron can be measured Wait. In addition, the penetration ultrasonic method has been widely used in the inspection of fiber-reinforced plastics and honeycomb structure materials. Ultrasonic holographic imaging technology has also been applied in some aspects.